i.prep 2

Engineered for integration.

Compact. Intelligent.

Completely open.

Independent channel precision, Python control, and true robotic access.

Built for the new scale of automation.

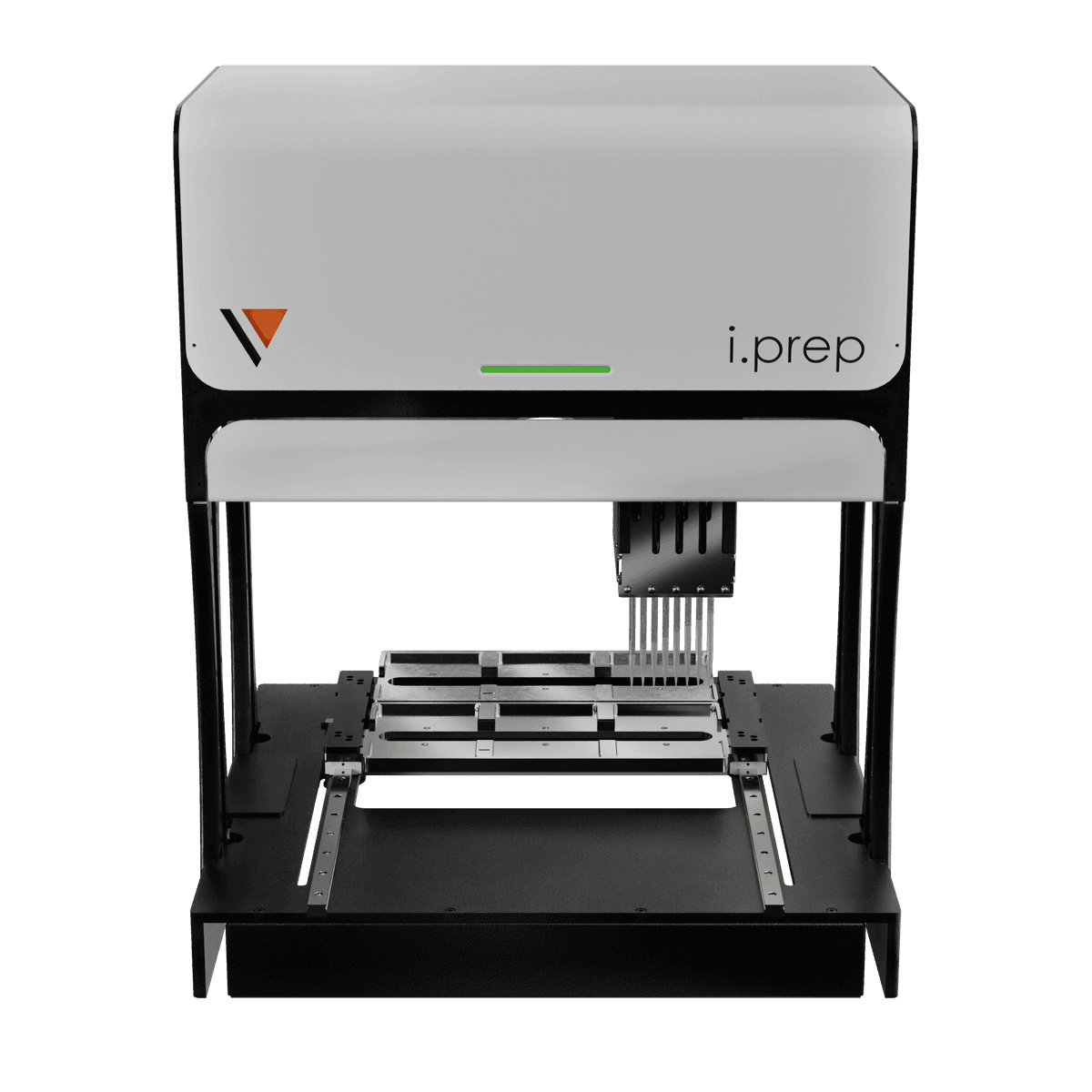

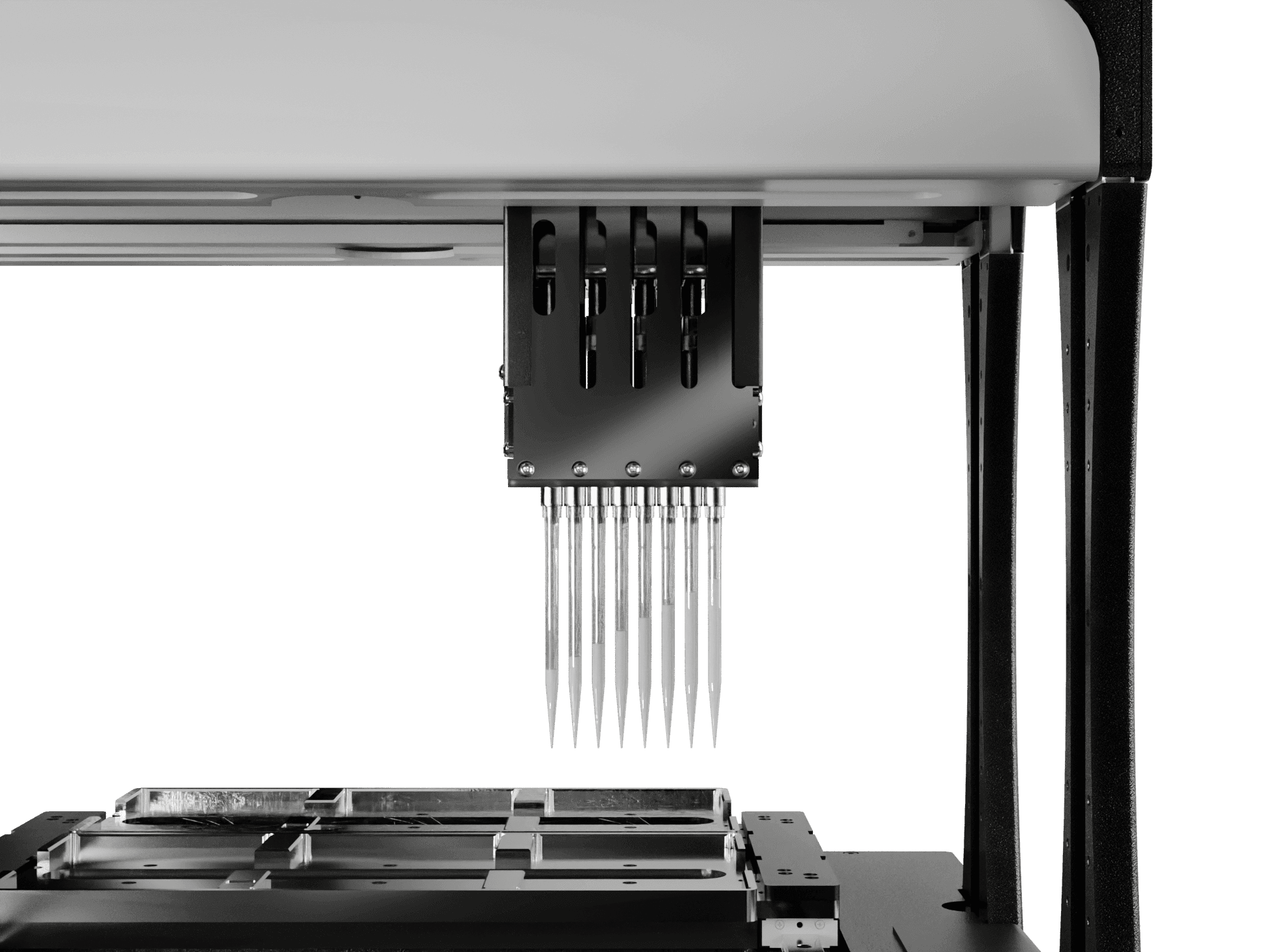

Precision in every channel.

Each pipette channel moves and aspirates independently, allowing true multi-tasking within a single run. Normalise, cherry-pick, or dispense to individual wells, i.prep 2 delivers flexible motion control without sacrificing speed or accuracy.

Open API.

Real-time control.

Take full command via REST + Python, with WebSocket telemetry for live status, errors, and events. Orchestrate tip handling, aspirate/dispense, and deck moves from your own code or scheduler. No black boxes, no workarounds. It’s open by design and controlled by you.

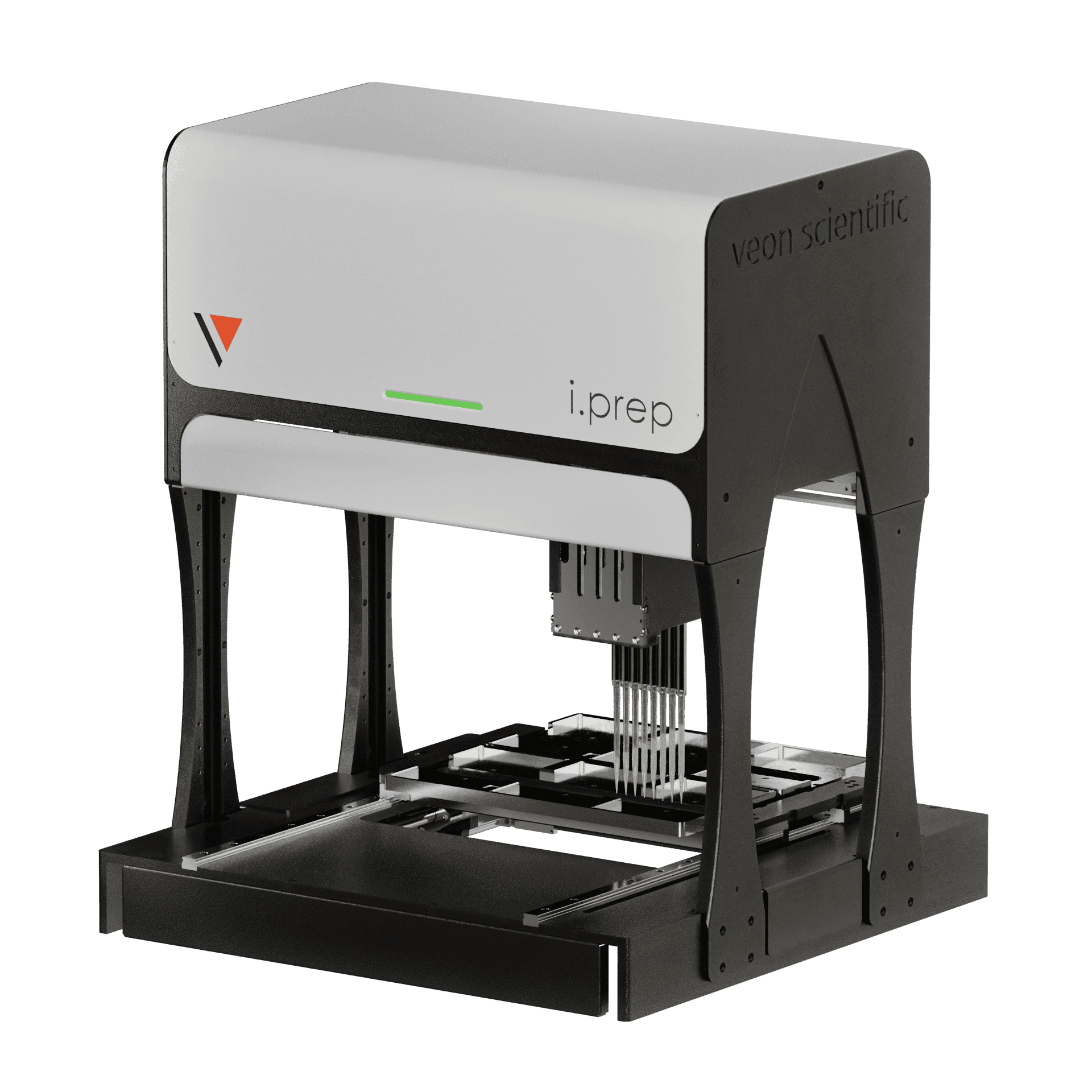

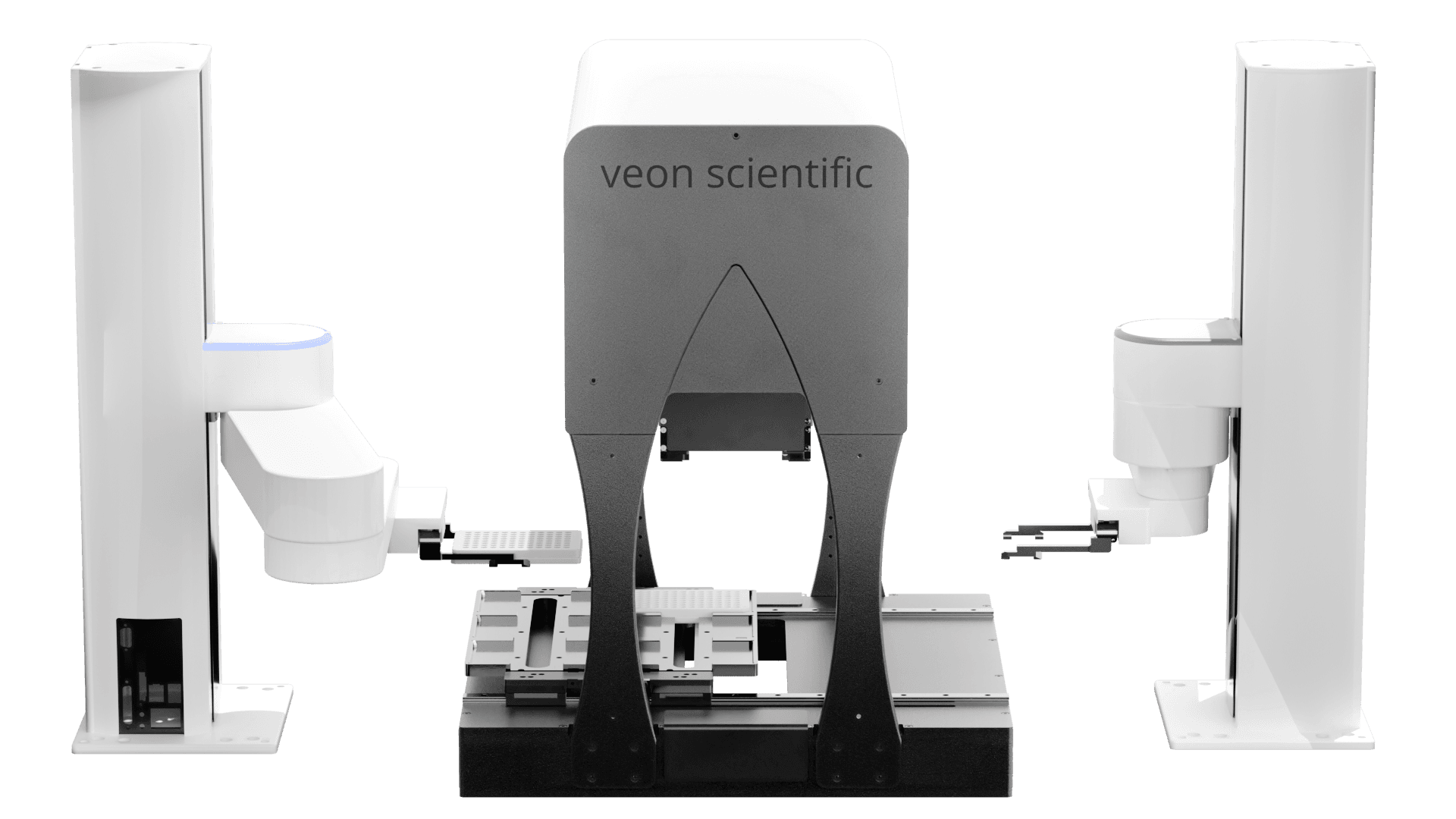

Access all areas.

Front, rear, or side, i.prep 2 is designed for reach. The open-frame architecture welcomes robotic arms, plate grippers, and human operators alike, making it the most integration-friendly compact liquid handler in its class.

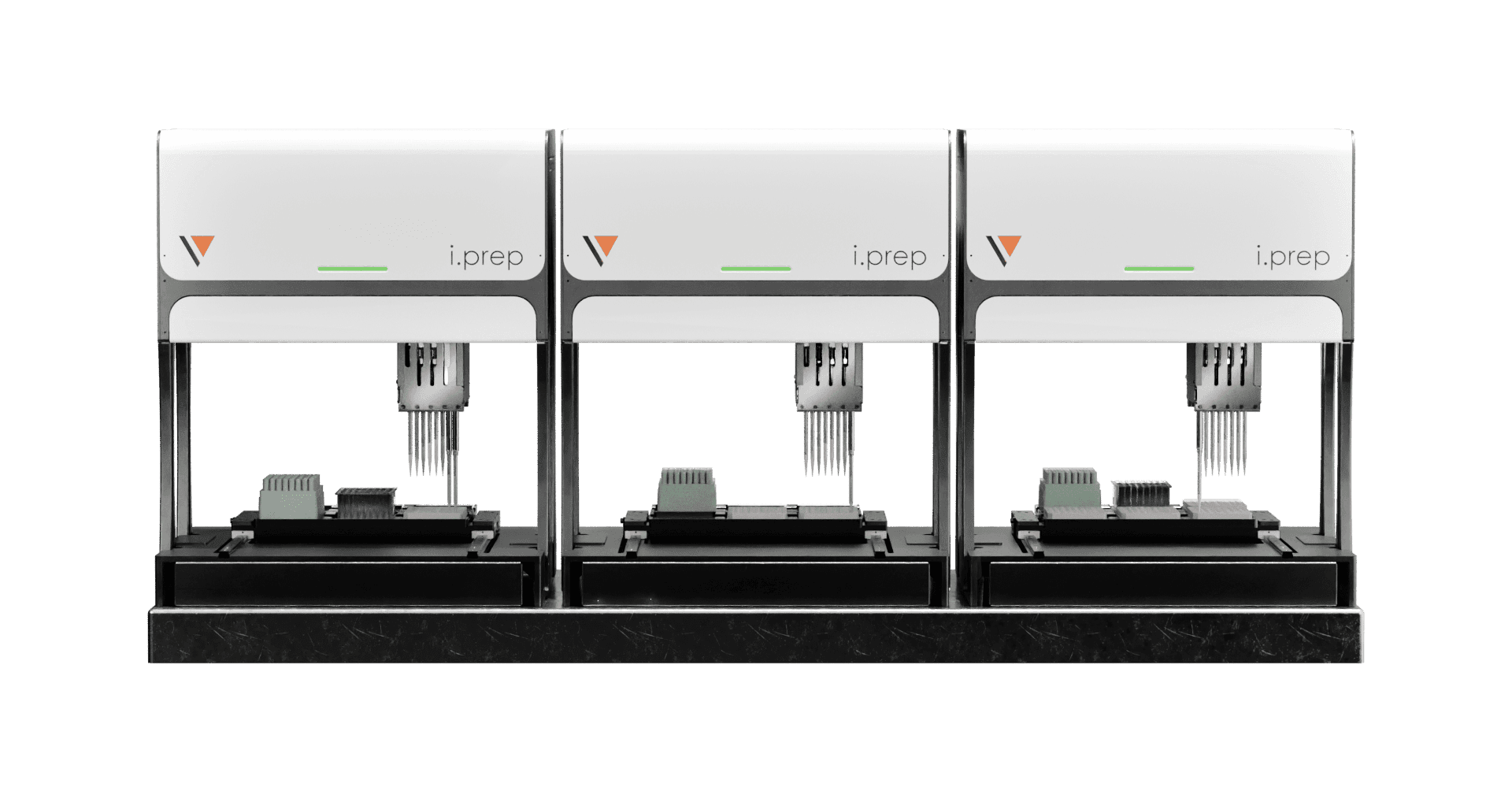

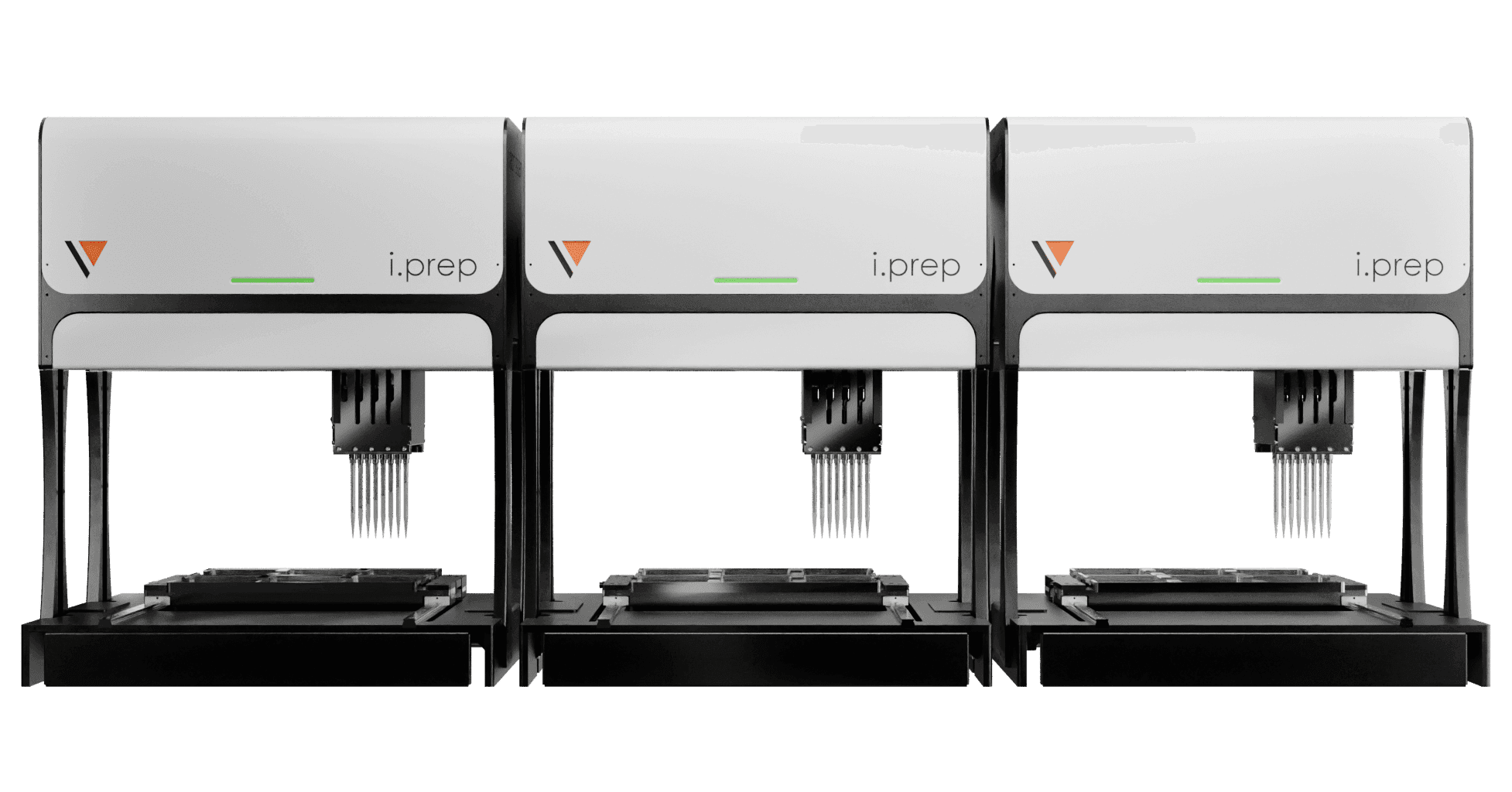

Small machines.

Big impact.

Instead of one complex system doing it all, have a cluster of simple, powerful instruments each optimised for a parallel task. Modular, compact, and controllable through an open API. The future of automation isn’t bigger. It’s smarter.

Designed for real automation.

Discrete channels

Precise control of liquid levels, cherry-picking, and normalisation without wasted motion. Run parallel operations or treat every channel as a standalone pipette.

Modular deck

Configurable 6-zone deck and 2 static zones for plates, reservoirs, and third-party modules, scalable to your workflow and easy to reconfigure.

Open API

REST, WebSocket, and Python SDK control give full command of every motion for seamless integration and automation.

Compact footprint

Powerful automation that fits where others can’t. Sits comfortably on your bench or inside a biosafety cabinet leaving space for everything else that matters.

Wide volume range

Handle anything from microlitre transfers to full-plate fills. Each channel delivers a true 1-1000µL working range with uncompromised accuracy across the span.

On-deck modules

Add heat, shake, or mix directly on the deck. i.prep 2 supports standard third-party heaters and shakers, so temperature control and agitation fit seamlessly into your workflow.

flow studio

No-code or all-code, it's your choice. Design protocols visually, simulate them in 3D, or script in Python within the same environment.

Workcell ready

Front, side, and rear access zones let robotic grippers load plates freely, making i.prep 2 the easiest platform to embed in a multi-instrument cell.

flow studio.

Automation you can see.

flow studio gives you a live 3D view of each i.prep 2, drag-and-drop method building, and instant access to the same Python and API layer underneath. Design workflows visually, then dive into code when you want full control.

Many instruments.

One flow studio.

Run a whole bench of i.prep 2 instruments from a single laptop. flow studio connects to multiple devices on your network, so you can switch between instruments in a click, push the same protocols to different rigs, and watch deck status and telemetry per system.

Python inside the instrument.

Instead of fighting vendor GUIs, you write Python. i.prep 2 executes your scripts on-device, giving you precise control of tips, channels, and motion while streaming telemetry back to your tools. Build protocols as code, version them in Git, and trigger them from schedulers, LIMS, or your own services without leaving your existing workflow.

Design in 3D.

Flow Studio gives you a live 3D canvas of the i.prep 2 deck, so you can see plates, tips, and channels exactly where they are in space. Build methods with a drag-and-drop interface that feels more like a modern editor than a lab tool.

AI Ready.

From model to method.

i.prep 2 exposes a clean API, structured telemetry, and reproducible Python protocols, so AI planners, optimisation loops, and LLM agents can design experiments while the instrument handles the liquid handling, turning model output directly into executed workflows.

Shape the next generation of lab automation

Access early adopter discounts, priority support, and direct collaboration with our engineering team.

Join the pioneer program

i.prep 2

Next generation liquid handling.

8 independent channels

1–1000 µL volume range

Pressure liquid level detection

Capacitive liquid level detection

6 ANSI/SLAS (SBS) zones

2 customisable off-deck zones

Third-party on-deck module support

Pipette technology

1, 4, 8 channels

1–1000 µL volume range

Air displacement

Pipette Specification

1 µL, 5.0% accuracy, 4.0% CV

50 µL, 2.0% accuracy, 0.75% CV

1000 µL, 1.0% accuracy, 0.75% CV

Size and weight

Height

640 mm (25.2 inches)

Width

532 mm (20.9 inches)

Depth

520 mm (20.4 inches)

Weight

35 kg (77 lb)

Connectivity

Wi-Fi

Ethernet

Power

Supply voltage

100–240 V AC, 50/60 Hz, 3.8 A

External power supply

48 V DC, 7.5 A

Operating conditions

Temperature

15°C to 40°C (59°F to 104°F)

Relative humidity

≤ 80%

Software

Minimum requirements

OS: Windows 10 Home / Professional

Memory: 4 GB RAM

Storage: 60 GB SSD

Processor: Intel Core m3 or above

Let’s talk

automation.

Whether you’re exploring i.prep 2, the Pioneer Program, or a custom integration, we’d love to hear what you’re building and how we can help.

Email us with a brief overview of your workflows, lab setup, and timelines, and we’ll route it to the right person on the team.

Phone

+44 (0)1234 417317

Mon–Fri, 9:00–17:30 (UK time)

Pioneer Program

Interested in becoming an early partner? Mention the Pioneer Program in your email and we’ll share next steps and availability.

Location

Bedford, United Kingdom

Supporting integrations and deployments globally.