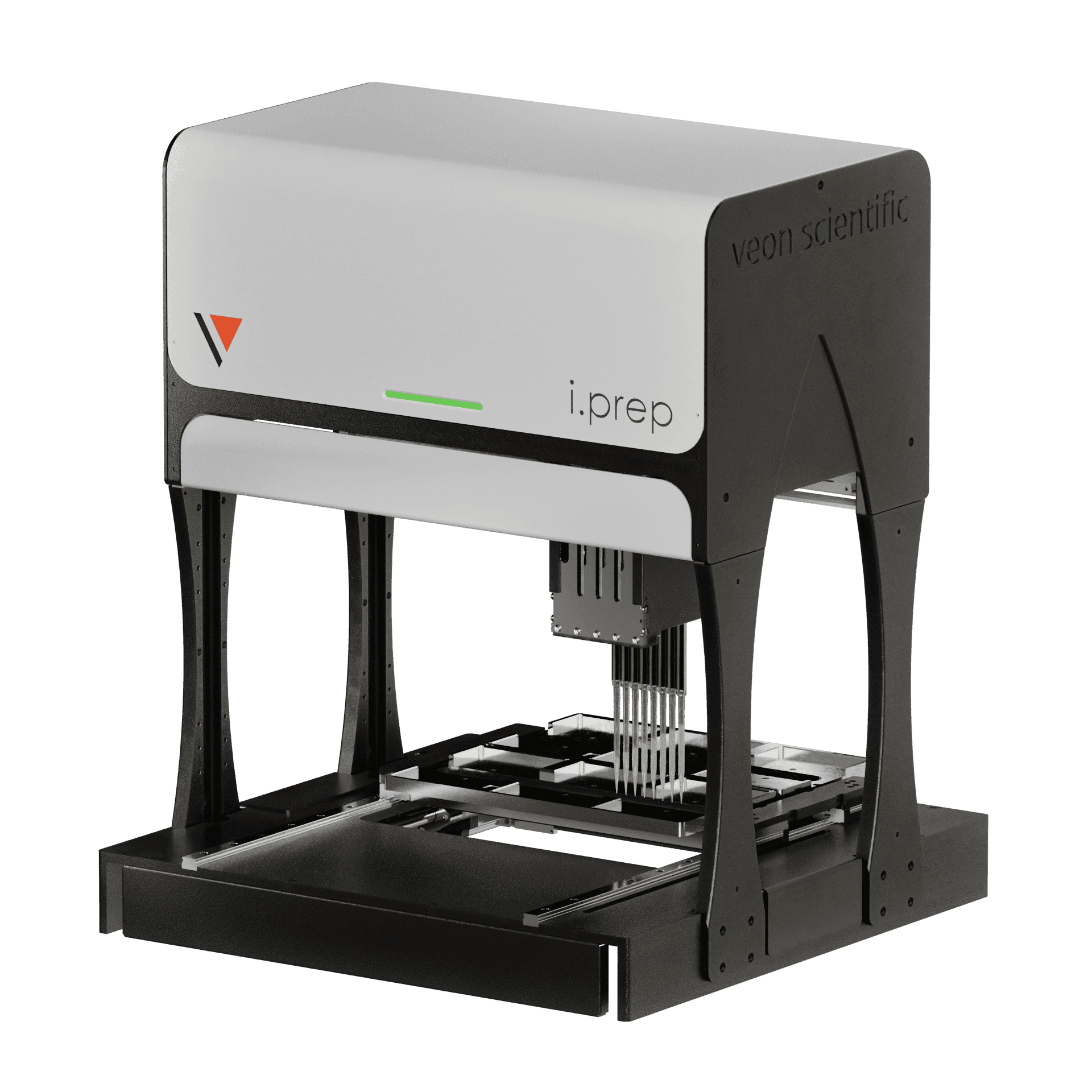

Adrian Hatton

Co-Founder

Adrian is co-founder and lead electrical engineer at Veon Scientific, shaping both the product roadmap and commercial strategy. With decades of experience in life-science instrumentation, spectroscopy, and lab automation, he works closely with customers to understand their workflows and turn requirements into reliable, scalable systems.